We are unable to envision a community without the need of Compressions. Compressions have realized their value in virtually all app starting from family things to complicated analysis equipments. Though there have been controversies the Compressions cause a menace to the surroundings, the advancements in Compression manufacturing technologies have presented arrival towards the eco-friendly Compressions. Compression manufacturers can now recycle and produce new Compression-type material merchandise out from the applied Compressions. You will certainly be well aware of the truth that Compression Molding is widely used to manufacture the Compression goods. Today’s Molding is quite very much innovative and not the same as what was in the beginning invented. Just continue studying this content to understand by pointing out Molding tactics.

Compression Molding is not a fresh principle created today. Molding Compressions into beneficial merchandise exits since the origin of manmade Compression-type material during 1851. The entire process of warming Compressions and melting the molten substance to obtain the model of the mould may be the fundamental principle right behind Compression Molding. Though the concept of Molding remains to be the very same right now, this technologies have viewed several developments. Compression-type Molding obtained massive importance during the period of 2nd Community Warfare due to the interest in the Compression health-related silicone rubber molding. The truth is the Compression producers where by fighting to satisfy the demand for the Compression-type material merchandise during this period. This is certainly period when the Molding market received a brand new shift towards improvement.

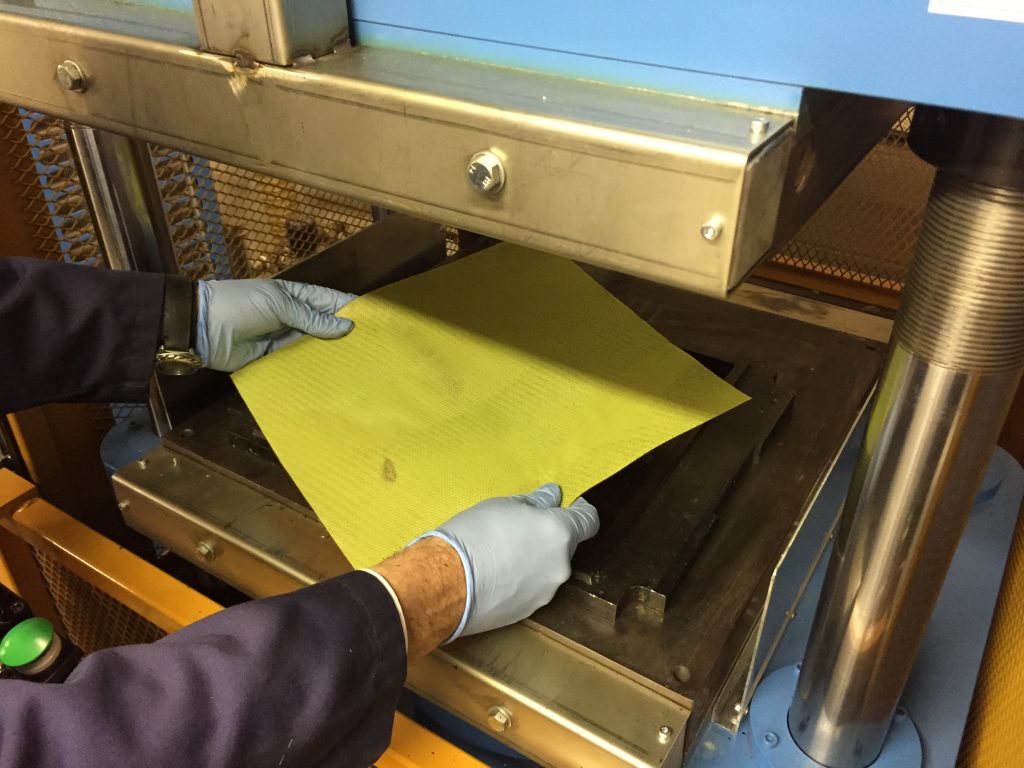

Although the principal reasoning behind Molding remains to be the same, the equipments employed by the Compression-type material suppliers have altered a whole lot. With the integration of newest personal computer technologies the production price of Compression is considerably greater right now. Unlike the olden days only once only refreshing Compression resources have been molded to beneficial items, nowadays with ecological understanding going up, Compression-type material Molding concentrates on using recycled materials. Moreover, the improvements in Molding technologies have made it feasible to produce products in every difficult forms.

The applications of Compression-type Compression Molding are practically limitless. Starting with basic Compression hold hand bags to complicated lifesaving devices – every single Compression merchandise made right now are by means of Compression Molding. Some of the common uses of Compression-type Molding are the producing of items such as packaging hand bags, vehicle pieces, drink containers and containers, laptop or computer add-ons etc.

Categories: General